That lawnmower that won’t start on the first Saturday of spring. The leaf blower that sputters and dies halfway through clearing the driveway. The generator that fails precisely when you need it most during a power outage. If you’ve experienced any of these frustrating moments, you already know that small gas engines demand respect and regular attention.

These compact powerhouses run our mowers, trimmers, tillers, and countless other essential garden tools, yet most of us treat them like appliances we can simply pull from the shed and expect to work flawlessly year after year. The reality is different. A small gas engine is a precise mechanical system that requires consistent care, proper storage, and occasional troubleshooting to deliver reliable performance season after season.

The good news? Maintaining these engines isn’t complicated or time-consuming. Understanding a few fundamental principles about fuel stability, oil requirements, and seasonal preparation will prevent most common failures. Proper off-season storage takes just fifteen minutes but can mean the difference between a machine that roars to life next spring and one that leaves you yanking a starter cord in frustration.

This guide walks you through everything you need to keep your equipment running smoothly, from routine maintenance tasks you can complete in your driveway to storage techniques that protect your investment during dormant months. Whether you’re a first-time homeowner puzzled by your mower’s carburetor or an experienced gardener looking to extend equipment lifespan while minimizing environmental impact, you’ll find practical solutions that work without requiring a mechanic’s expertise or specialty tools.

Understanding Your Small Gas Engine: The Basics That Matter

What Makes Small Gas Engines Different

Understanding the heart of your lawn equipment starts with recognizing that small gas engines come in two main varieties: 2-stroke and 4-stroke engines. Each has distinct characteristics that directly impact how you’ll maintain them throughout the seasons.

Two-stroke engines are the simpler cousins in the family. You’ll find them powering your string trimmers, leaf blowers, and chainsaws. These lightweight workhorses complete their power cycle in just two piston movements, which makes them incredibly efficient for their size. Here’s the catch though: they require you to mix oil directly into the gasoline, typically at ratios like 50:1 or 40:1. This oil-gas mixture lubricates the engine as it burns, which is why 2-stroke equipment produces that distinctive blue exhaust smoke. From a maintenance perspective, getting this fuel mixture right is absolutely critical. Too little oil and you’ll damage the engine; too much and you’ll foul the spark plug and create excess emissions.

Four-stroke engines, commonly found in lawn mowers, pressure washers, and larger equipment, operate more like your car’s engine. They have a separate oil reservoir, which means you fill the gas tank with pure gasoline and check the oil level separately. These engines complete their power cycle in four piston movements, making them quieter, more fuel-efficient, and cleaner-burning than their 2-stroke counterparts. The trade-off? They’re heavier and require more routine maintenance, including regular oil changes and air filter replacements.

Why does this matter for your maintenance routine? Simply put, each engine type has vulnerabilities tied to its design. Two-stroke engines are prone to carbon buildup from that oil-fuel mixture and can suffer quickly from stale fuel. Four-stroke engines need consistent oil changes and are more sensitive to running low on oil. Knowing which type you’re working with helps you anticipate problems before they strand you mid-mow on a Saturday afternoon.

The Parts That Need Your Attention Most

Let me be honest with you – not every part of your mower or trimmer needs equal attention. Just like in gardening, where certain plants demand more care than others, your small gas engine has a few critical components that really make or break performance. Focus your energy here, and you’ll save yourself considerable frustration.

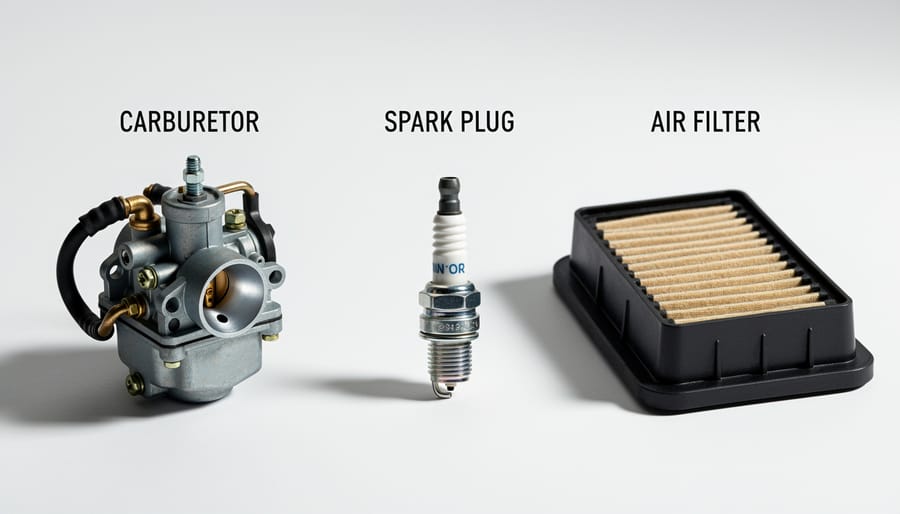

The carburetor is your engine’s heart, mixing fuel and air in precise ratios. When it gets gummed up with old fuel residue, your equipment becomes temperamental or won’t start at all. Think of it like clogged irrigation lines in your garden – everything downstream suffers. Regular cleaning prevents this headache entirely.

Your spark plug might be tiny, but it’s mighty important. This component ignites the fuel mixture, and a fouled or worn plug means weak starts or none at all. The good news? They’re inexpensive and incredibly easy to replace. Check it seasonally and swap it out annually.

The air filter protects your engine from dust, grass clippings, and debris – basically the same stuff that coats your garden tools after a long day outside. A clogged filter chokes your engine, reducing power and efficiency while increasing fuel consumption. Clean or replace it regularly, especially during heavy-use seasons.

Finally, your fuel system deserves respect. Old gasoline breaks down, leaving varnish deposits that wreak havoc. Using fresh fuel and adding a stabilizer, particularly before storage, prevents most fuel-related problems. This simple habit alone eliminates the majority of springtime starting issues that frustrate gardeners everywhere.

Essential Maintenance Tasks That Prevent Most Problems

Oil Changes: The Single Best Thing You Can Do

I’ve learned this lesson the hard way more times than I’d like to admit: if you’re going to do just one maintenance task on your mower, trimmer, or other four-stroke equipment, make it regular oil changes. Think of oil as your engine’s lifeblood, keeping all those metal parts from grinding against each other like sandpaper on wood.

For most small gas engines, you’ll want to change the oil after the first five hours of use on new equipment, then every 25-50 hours of operation thereafter. If you’re a weekend gardener, that usually means once per season. Check your owner’s manual for specific recommendations, but when in doubt, err on the side of changing it more often.

Here’s how to do it right: First, run your engine for a few minutes to warm the oil, making it flow more easily. Turn off the engine and disconnect the spark plug wire for safety. Locate the oil drain plug or tip the equipment to drain from the fill tube into an approved container. Once drained, replace the drain plug and refill with the manufacturer’s recommended oil type, typically SAE 30 for warmer months or 10W-30 for variable temperatures.

Here’s the sustainability part that matters: never pour used oil down drains or onto the ground. Take it to any auto parts store or recycling center that accepts used oil. Most take it for free, and it gets recycled into new products. You’re protecting your equipment and the environment simultaneously.

Spark Plug Care and Replacement

Your mower’s spark plug is like the starter pistol at a race—without it firing properly, nothing else matters. The good news? Maintaining this tiny component takes just minutes and prevents most starting headaches.

Start by removing the spark plug using a spark plug socket (usually 5/8 or 13/16 inch). Before you do anything else, check the gap between the center and side electrodes using a gap tool—most small engines need 0.030 inches, but always verify in your manual. A worn plug often shows a wider gap, black carbon buildup, or electrode erosion.

Here’s what tells you it’s replacement time: difficulty starting, rough idling, poor fuel economy, or a plug that looks fouled with oil or carbon deposits. Even if it looks okay, replace plugs annually as preventative care—they’re inexpensive insurance against frustration.

To clean a moderately dirty plug, use a wire brush and spray cleaner. Wipe it thoroughly and let it dry completely. Reset the gap if needed by gently bending the side electrode.

When installing, hand-thread the plug first to avoid cross-threading, then tighten snugly with your socket wrench—not too tight! Over-torquing damages both the plug and engine threads.

This simple five-minute check each season keeps your equipment reliable and reduces the environmental impact of disposing improperly running engines that waste fuel. It’s one of those satisfying tasks where minimal effort yields maximum results.

Air Filter Maintenance: Your Engine’s Lungs

Think of your air filter as your engine’s lungs—when they’re clogged, everything suffers. I learned this lesson the hard way when my mower started sputtering mid-season, and I discovered the filter looked like it had been through a dust storm!

Most small engines use either foam or paper air filters. Foam filters are reusable and perfect for dusty conditions—simply wash them in warm, soapy water, let them dry completely, then apply a light coating of clean engine oil before reinstalling. Paper filters, common on newer equipment, should be tapped gently to remove loose debris or replaced when visibly dirty. Never try washing paper filters, as this damages the fibers.

Check your air filter every 25 hours of operation, or more frequently if you’re mowing in dry, dusty conditions. A clogged filter forces your engine to work harder, burning more fuel and reducing power—hardly sustainable or efficient! During peak season, I keep a spare filter handy so maintenance never interrupts my weekend projects.

Here’s a sustainable tip: clean foam filters can last several seasons with proper care, reducing waste and saving money. Just remember, a five-minute filter check beats an expensive repair bill every time.

Keeping the Fuel System Clean and Happy

Think of your small engine’s fuel system as your garden itself – what you put in matters tremendously. I learned this the hard way when my reliable mower sputtered to a stop mid-July, leaving half the lawn looking like a shaggy meadow. The culprit? Bad fuel and my own neglect of basic fuel system care.

Fresh fuel is absolutely essential. Gasoline begins breaking down after about 30 days, forming gums and varnishes that clog carburetors faster than you’d believe. I now buy only what I’ll use in a month, keeping it in an approved container away from sunlight. It’s a simple habit that prevents countless headaches.

Here’s where modern fuels get tricky: most pump gas contains ethanol, which attracts moisture and corrodes fuel system components. For equipment that sits idle between uses, ethanol is genuinely problematic. Whenever possible, I use ethanol-free gas for my outdoor power equipment. Yes, it costs more, but the savings in repair bills and frustration make it worthwhile.

Fuel stabilizers are your insurance policy. Add stabilizer to your fuel can immediately after purchase, not just before storage. This proactive approach keeps fuel fresh and protects against ethanol damage year-round. I keep a bottle in my garden shed right next to my gas can as a visual reminder.

Don’t forget fuel filters – those inexpensive little guardians of your carburetor. Replace them annually or whenever they appear dirty. It’s a five-minute task that prevents expensive repairs down the road, much like mulching prevents weeds in your garden beds.

Blade and Deck Care (For Mowers)

Your mower’s blade and deck deserve attention—they directly impact how hard your engine works. Dull blades tear grass rather than cutting cleanly, forcing the engine to work harder and consume more fuel. Regular blade maintenance means sharpening at least twice per season, or whenever you notice ragged grass tips.

Don’t neglect what’s underneath. Grass clippings build up under the deck, creating extra weight and restricting airflow. After each few mows, tip your mower safely (spark plug side up) and scrape away debris with a putty knife. A clean deck means better airflow and less resistance. Remember, sharp blades reduce engine strain, extending your equipment’s life while delivering that crisp, healthy cut your lawn deserves.

The Right Way to Store Gas-Powered Equipment

End-of-Season Storage: Preparing for Winter

When Jack Frost starts nipping at your nose, it’s time to think about tucking your lawn mower and other gas-powered equipment away for their winter rest. I learned this lesson the hard way years ago when I simply rolled my mower into the shed one November afternoon, thinking I’d deal with it come spring. Let’s just say that March morning involved a lot of muttering, a gummed-up carburetor, and an expensive trip to the repair shop. Trust me, spending an hour now will save you hours of headache and potentially hundreds of dollars later.

The big fuel debate comes first: should you stabilize or drain? Both approaches work, but I’ve found that adding fuel stabilizer to a nearly full tank is the more reliable option for most homeowners. Fill your tank about 90 percent full, add the appropriate amount of stabilizer following the bottle’s instructions, then run the engine for five to ten minutes. This circulates the treated fuel throughout the system, coating all those delicate carburetor passages and preventing the varnish buildup that causes spring startup nightmares. The full tank also prevents moisture condensation inside, which is especially important in humid climates.

If you prefer draining instead, run the engine until it dies from fuel starvation after shutting off the fuel valve. This works well too, though some fuel residue always remains in the carburetor. Either way, stale gasoline is your enemy, so never leave untreated fuel sitting all winter.

Next up is an oil change, even if you changed it mid-season. Used oil contains acids, moisture, and combustion byproducts that can corrode engine internals during storage. Fresh oil provides a protective coating throughout the winter months. While you’re at it, replace or clean the air filter. A clean filter prevents dust and debris from settling into the carburetor during storage.

Give your equipment a thorough cleaning before storage. Caked-on grass clippings and dirt trap moisture against metal surfaces, promoting rust. For mowers, scrape the underside of the deck and spray it down with water, letting it dry completely. Wipe down the engine cooling fins too, as debris-clogged fins can cause overheating issues next season.

Remove the spark plug and add a tablespoon of fresh oil into the cylinder, then pull the starter cord slowly several times to distribute it. This creates a protective coating on cylinder walls and piston rings. Replace with a new spark plug or reinstall the old one.

Battery care deserves special attention. Remove the battery from electric-start equipment and store it in a cool, dry location, ideally connected to a trickle charger or maintenance charger. Batteries left in cold equipment can freeze and crack. Check fluid levels in serviceable batteries and top up with distilled water if needed.

Finally, choose your storage location wisely. A dry, covered area protects against moisture, which is rust’s best friend. Cover your equipment with a breathable tarp or sheet rather than plastic, which traps condensation. Elevate machines slightly off concrete floors using wood blocks to prevent moisture wicking. And speaking of unwanted visitors, steel wool stuffed into exhaust openings keeps mice from building cozy nests in your engine over winter. These small steps ensure your equipment emerges ready to work when gardening season returns.

Mid-Season Storage: When Equipment Sits for Weeks

Even during the growing season, there are times when your mower, trimmer, or other gas-powered equipment might sit idle for a few weeks. Maybe you’re heading on vacation, recovering from an injury, or the weather just isn’t cooperating. Whatever the reason, taking a few simple steps during these mid-season breaks can save you from frustrating restart problems and keep your equipment running reliably.

The biggest culprit during short-term storage is fuel degradation. Modern ethanol-blended gasoline can start breaking down in as little as two weeks, especially in warm weather. When fuel sits in your carburetor and fuel lines, it begins to oxidize and separate, forming gummy deposits that clog tiny passages. I learned this lesson the hard way after a three-week vacation left my trimmer completely unresponsive.

For any period longer than two weeks, add fuel stabilizer to your gas tank before storing. Run the engine for about five minutes to ensure the treated fuel circulates through the entire fuel system. This simple step prevents oxidation and keeps fuel fresh for up to three months, making it perfect for those mid-season gaps.

Store your equipment in a covered location away from direct sun and rain. Even if you don’t have a shed, a heavy-duty tarp creates adequate protection. Position machines on level ground to prevent fuel or oil from settling unevenly in the engine, which can cause starting difficulties later.

Storage Location and Protection

Finding the right home for your lawn mower, trimmer, or other gas-powered equipment makes all the difference in how well they’ll serve you season after season. Think of it this way: you wouldn’t leave your garden tools out in the rain, and your small gas engines deserve that same consideration.

Your best storage option is a dry, well-ventilated space like a garage or shed. These enclosed areas shield your equipment from rain, snow, and direct sunlight, all of which can degrade fuel systems, rubber components, and protective finishes. If you don’t have indoor space, a high-quality waterproof cover designed for outdoor power equipment is your next best choice. Just remember that outdoor storage, even with a cover, means more frequent maintenance checks.

Temperature extremes can be tough on small engines. While you can’t always control the weather, choosing a storage spot away from heating vents or direct sun helps prevent fuel evaporation and condensation buildup. Speaking of moisture, it’s the silent enemy of gas engines. Consider placing moisture-absorbing products near your equipment or ensuring your storage area has adequate airflow. A concrete floor is better than dirt, which releases moisture.

proper equipment storage extends beyond just location. Organization matters too. Store equipment on level ground to prevent fuel and oil from settling incorrectly. Keep gas cans away from living spaces and out of children’s reach. Wall-mounted racks or designated corners help prevent accidental tip-overs and make spring startup much easier. When everything has its place, you’ll spend less time hunting for equipment and more time enjoying your garden.

Troubleshooting Common Small Engine Problems

When Your Engine Won’t Start

We’ve all been there – you pull the starter cord on your mower or trimmer, and nothing happens. Before you panic or load it into the car for an expensive repair visit, let’s walk through some simple checks that solve most starting problems.

Start with the absolute basics: fuel. I know it sounds too simple, but you’d be surprised how often this is the culprit! Check if there’s gas in the tank, and give it a sniff. Old fuel that’s been sitting for months develops a stale, varnish-like smell and won’t combust properly. If your gas is questionable, drain it and refill with fresh fuel. This alone solves about a third of starting issues I encounter.

Next, examine your spark plug. Remove it using a spark plug socket – it’s usually right on top of the engine. A healthy spark plug has a light tan or grey electrode. If yours is black, sooty, or wet with fuel, it needs cleaning or replacement. While it’s out, test for spark by reconnecting the wire, grounding the plug threads against the engine, and pulling the starter cord. You should see a bright blue spark. No spark? Replace the plug before investigating further.

Check your air filter too. A clogged filter chokes the engine, preventing proper air-fuel mixture. Remove it and hold it up to light – if you can’t see through it, clean or replace it.

If you’ve verified fuel, spark, and air but still have no luck, the carburetor may need cleaning, especially after long storage periods. This involves more detailed work but remains manageable for patient DIYers following your owner’s manual.

Rough Running and Power Loss

When your mower or trimmer starts acting up with rough running, you’re not alone in feeling frustrated. Let’s walk through the most common culprits and get your equipment humming smoothly again.

Surging and sputtering often point to fuel delivery problems. Your carburetor might be partially clogged with old fuel residue or debris. Start by checking your fuel quality—gasoline older than 30 days can gum up the works. Drain old fuel and replace it with fresh gas mixed with a fuel stabilizer for longer life. While you’re at it, inspect the air filter. A dirty filter restricts airflow, creating an imbalanced fuel-to-air mixture that causes rough running. Clean foam filters with soap and water, and replace paper filters when they look dirty.

Power loss that develops gradually usually stems from carbon buildup on the spark plug or a loose spark plug connection. Remove the plug and examine it—if it’s black and sooty, clean it with a wire brush or replace it. This simple five-minute fix often restores lost power immediately.

Overheating deserves special attention since it can cause permanent engine damage. Clear away grass clippings and debris from cooling fins regularly. Overheating can also indicate mower blade issues that create excessive drag on the engine.

By addressing these common issues promptly, you’ll extend your engine’s life while reducing waste—a win for your wallet and the environment.

When to Call a Professional

Most small gas engine maintenance falls comfortably within DIY territory, and honestly, it’s empowering to handle your own tune-ups and seasonal prep. Tasks like changing spark plugs, cleaning air filters, replacing fuel lines, and adjusting carburetors are weekend-friendly projects that save money and build your confidence. With a basic tool set and patience, you’ll find these jobs quite manageable.

However, some situations warrant professional attention. If your engine has significant internal damage, like scored cylinder walls or a damaged crankshaft, the specialized tools and expertise required make professional repair more practical. Similarly, persistent problems that defy troubleshooting, electrical system failures beyond basic spark plug issues, or warranty-covered equipment should go to qualified technicians.

Safety always comes first. If you’re uncomfortable working with fuel systems, if a repair requires engine disassembly you’re not confident tackling, or if you simply don’t have time for trial-and-error, calling a professional is the wise choice. Many garden equipment shops offer reasonable diagnostic fees that can actually save you money by pinpointing problems accurately. Think of professionals as partners in keeping your equipment running sustainably longer, not as admissions of defeat. There’s real value in knowing your limits and making cost-effective decisions that keep your lawn care tools serving you reliably for years to come.

Sustainable Practices for Small Engine Care

Reducing Emissions Through Proper Maintenance

Here’s a truth that might surprise you: a well-maintained small gas engine can produce up to 40% fewer emissions than a neglected one. That’s a significant difference, and it matters for both the air we breathe and the planet we’re trying to protect. When you keep your mower, trimmer, or chainsaw running smoothly, you’re not just extending its life, you’re actually becoming part of the solution to air quality problems.

Think about it this way: a dirty air filter forces your engine to work harder, burning more fuel and releasing more pollutants. Similarly, old spark plugs cause incomplete combustion, sending unburned fuel straight into the atmosphere. Regular maintenance fixes these issues before they become environmental problems. Simple tasks like changing the oil, replacing spark plugs annually, and keeping the air filter clean ensure your engine burns fuel efficiently and completely.

The fuel economy benefits are real too. A properly tuned engine uses less gas to do the same work, which means fewer trips to the gas station and less money spent over the season. You’ll notice the difference in how smoothly your equipment runs and how much further a tank of gas takes you. This is sustainable gardening in action, making your lawn care routine better for your wallet and the environment at the same time.

Responsible Disposal and Recycling

When your small gas engine finally reaches the end of its useful life, or when you’re dealing with old fuel, used oil, and worn-out parts, disposing of these materials responsibly is absolutely essential for protecting our environment. I know it’s tempting to just toss things in the trash or pour liquids down the drain, but these shortcuts can contaminate groundwater and harm local ecosystems.

Let’s start with used oil, which is actually one of the easiest items to recycle. Most auto parts stores, quick-lube facilities, and municipal recycling centers accept used motor oil completely free of charge. Just drain your oil into a clean, sealed container and bring it in. A single quart of improperly disposed oil can contaminate up to 250,000 gallons of water, so this simple step makes a huge difference.

Old gasoline requires special handling too. Never pour it on the ground or into storm drains. Contact your local hazardous waste facility to learn about collection days or drop-off locations. Many communities hold seasonal collection events specifically for household hazardous waste, including old fuel and oil-soaked rags.

When it comes to the engine itself, consider donating still-functional equipment to community gardens, vocational schools, or repair cafes where it can be refurbished. Scrap metal recyclers will accept non-working engines and can properly handle the remaining fluids. Some manufacturers even offer trade-in or recycling programs for old equipment when you purchase new models, often providing incentives for choosing more efficient or electric alternatives that align with sustainable gardening practices.

Tools and Products That Make Maintenance Easier

The Basic Toolkit for Small Engine Maintenance

You don’t need a garage full of expensive equipment to keep your mower, trimmer, or generator running smoothly. A modest toolkit can handle 90% of small engine maintenance tasks, and building one gradually makes perfect sense for most homeowners.

Start with a quality socket set that includes both metric and standard sizes. Most small engines use 10mm, 13mm, and spark plug sockets most frequently. I learned this the hard way after buying three separate wrenches before investing in a complete set. A socket wrench with an extension bar makes removing air filters and accessing tucked-away bolts much easier.

Add a few essentials: a spark plug gap tool, an adjustable wrench, needle-nose pliers, and a set of screwdrivers with both flathead and Phillips heads. For oil changes, an inexpensive oil extractor pump saves your back and prevents messy spills, especially on equipment without convenient drain plugs.

Don’t overlook basic supplies like shop rags, a drip pan, and a fuel stabilizer measuring cup. A wire brush helps clean spark plugs and removes debris from cooling fins, extending your engine’s life between major services.

Budget-friendly options work perfectly fine. Many hardware stores offer starter mechanic sets for under fifty dollars that include everything mentioned above. As you become more comfortable with maintenance, you can add specialized tools like compression testers or carburetor adjustment tools. Remember, proper maintenance with basic tools beats neglect with fancy equipment every time.

Recommended Maintenance Products

After years of maintaining lawn equipment and talking with fellow gardeners, I’ve learned that using quality maintenance products isn’t about spending more—it’s about spending smart. The right products protect your investment and keep your mower, trimmer, or tiller running reliably season after season.

For engine oil, I consistently recommend Briggs & Stratton SAE 30 or their synthetic 5W-30. These oils are specifically formulated for small air-cooled engines and provide excellent protection during the temperature extremes your equipment experiences. Synthetic oil costs more upfront, but it extends engine life and handles heat better, making it worthwhile for premium equipment or if you run your machines hard.

Fuel stabilizer is non-negotiable in my book. STA-BIL Storage formula has proven itself time and again, preventing the gummy deposits that ruin carburetors during off-season storage. Add it to fresh fuel before storing, and your spring startup becomes dramatically easier. For equipment that sits between uses, their 360 Protection formula works in fuel year-round.

Sea Foam Motor Treatment serves double duty as both a fuel system cleaner and storage prep solution. I’ve revived countless sputtering engines with this product. It dissolves varnish, cleans injectors, and removes moisture—all common culprits behind poor performance.

Don’t overlook air filter maintenance either. Using genuine manufacturer filters or quality aftermarket options like those from Stens ensures proper fitment and filtration. A $5 filter protects a $300 engine, making it the easiest insurance policy you’ll ever buy.

Finally, keeping a small bottle of carburetor cleaner spray and some fresh spark plugs on hand means you’re prepared for regular maintenance and quick troubleshooting. These simple products prevent most common problems and support the sustainable practice of repairing rather than replacing equipment.

Taking care of your small gas engine doesn’t require a mechanic’s expertise or hours of your weekend. The truth is, spending just 15 to 30 minutes on basic maintenance after each use and a bit more attention before storage can save you hundreds of dollars in repairs and the frustration of equipment that won’t start when you need it most. Think of it as an investment with guaranteed returns: every oil change, every cleaned spark plug, and every properly stored fuel tank adds months or even years to your equipment’s life.

If you’re new to engine maintenance, start small. Begin with the simplest tasks like checking the oil level and cleaning debris from the exterior. As you gain confidence, move on to changing the oil, replacing spark plugs, and adjusting the carburetor. You’ll be surprised how quickly these tasks become second nature, and there’s genuine satisfaction in knowing you can keep your own equipment running smoothly.

Remember, every lawn mower, trimmer, and leaf blower in your shed represents a significant investment. By taking control of their maintenance, you’re not just saving money; you’re reducing waste, supporting sustainable practices, and ensuring your tools are ready whenever inspiration strikes in the garden. Your equipment will reward your attention with reliable performance season after season. Ready to expand your gardening knowledge? Explore our other practical guides and resources to help you create and maintain the beautiful, healthy outdoor space you envision.